SUSTAINABILITY

Sustainability

Reductions of Usage, Consumption and Waste Disposal

04/04/2022

Reductions of Usage, Consumption and Waste Disposal

The Company recognizes the importance of environmental care, efficient use of resources and environmental impact prevention in every aspect such as water management, waste management and reduction of greenhouse gas emissions.

Water Management (SD’s UN’s Goal 6 Clean water and Sanitation)

The Company uses tap water in production processes and in office buildings. Therefore, the Company regularly maintains and inspects the water distribution system in production processes to meet standards. The Company collects data on water use in every sector to enable the Company to effectively improve water resource management.

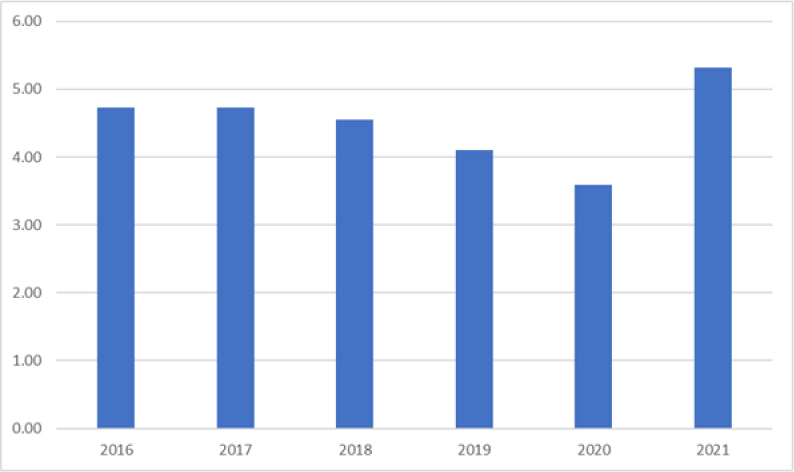

In 2021, the Company had a water consumption of 5.32 (Te)/ Production Volume (Te), which is an increase compared to the year 2020 with a water consumption of 3.59 (Te)/ Production Volume (Te). The amount of water used compared to the production volume increased due to the decrease in the total production volume while using water at the boiler and the use of water in the main production process still requires at the normal level.

Furthermore, the Company regularly monitors the quality of water disposal from the Company’s factories on an annual basis to prevent and monitor potential environmental impacts.

Waste Management (SD’s UN’s Goal 12 Responsible Consumption and Production)

The Company has systematic garbage and waste management in the business operation process according to the 3Rs principle (Reduce, Reuse, Recycle). The Company has an effective system for sorting waste into categories along with building awareness and participation among the people involved.

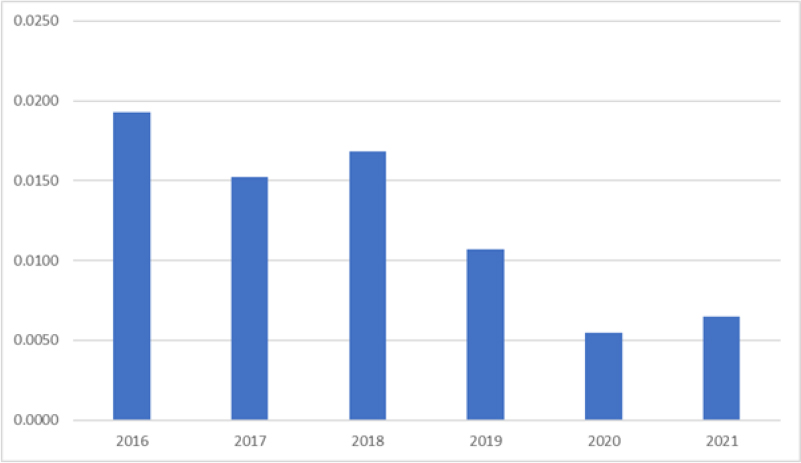

In 2021, the Company's waste volume is 0.0065 (Te)/ Production Volume (Te), which is an increase compared to 2020 with a waste volume of 0.0055 (Te)/ Production Volume (Te). The amount of waste compared to the production volume has increased due to cleaning and maintenance the production area during the past year. Therefore, there is an increase in the level of waste while the production volume was declined

There is a selection process to choose waste collector services who strictly follow the legal requirements and care for the health and safety of employees and nearby communities.

In addition, the Company regularly monitors environment quality on a yearly basis to prevent occupational health and external environmental issues.

Testing Occupational Health, Work Environments and External Environments

Thai Poly Acrylic Public Company Limited has evaluated and analyzed our work environments in 2021 to prevent occupational health and external environmental issues

Management to Reduce Greenhouse Gases (SD’s UN’s Goal 13 Climate Action)

Energy is extremely essential in most activities of the Company. However, energy consumption contributes to greenhouse gas emissions and causes climate change.

One of the Company’s targets is to improve greenhouse gas management. The Company collects data on sources of greenhouse gases emitted from the Company’s activities to aid the plan for greenhouse gas reduction.

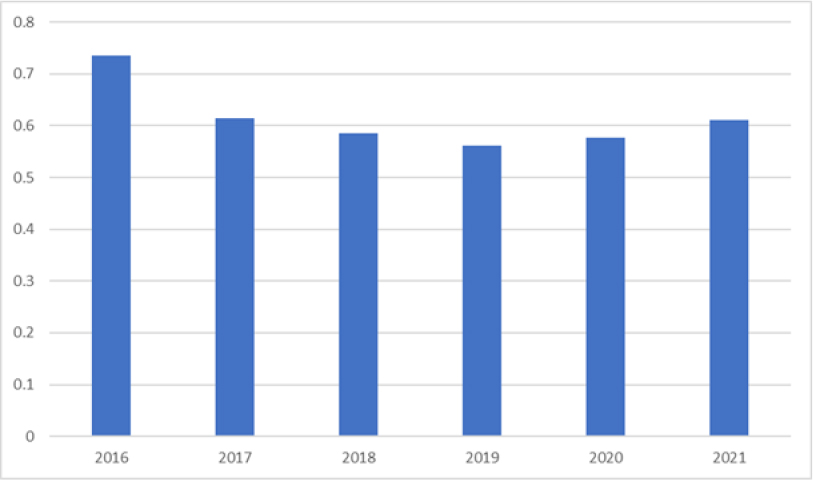

In 2021, the company has CO2 emissions of 0.611 (Te)/ Production Volume (Te), which is an increase compared to 2020 with a CO2 emission of 0.577 (Te)/ Production Volume (Te). The amount of CO2 emissions compared to the production volume increased due to the decrease in total production while using fuel at the boiler and the use of electricity in the production process which is the main process of CO2 emissions still required at the normal level.

Energy Management (SD’s UN’s Goal 7 Affordable and Clean Energy)

The Company recognizes the importance of energy management in the whole process while emphasizes on energy efficiency in every company activity. Renewable energy, sources of clean energy and new technology that can reduce pollution with sustainable effects on the environment are being explored and implemented in several activities of the company.

The Company prepares energy management reports, energy management policies and has energy management work groups. Energy management goals and plans are made on an annual basis.

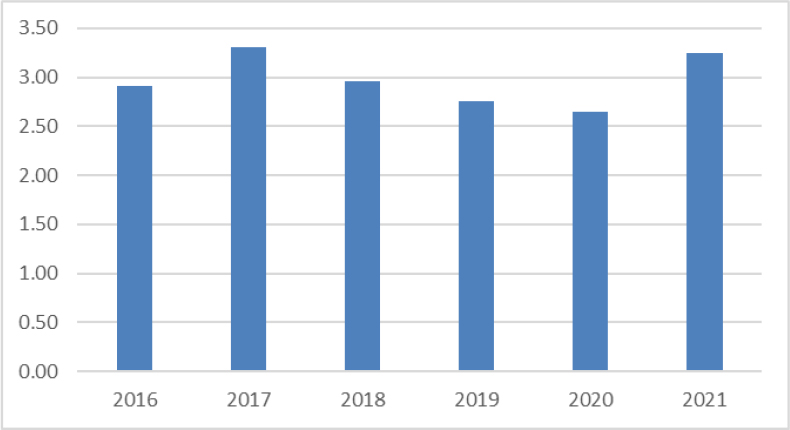

In 2021, the company's energy consumption is 3.25 (MWh)/ Production Volume (Te), which is an increase compared to the year 2020 with 2.65 (MWh)/ Production Volume (Te). Energy consumption compared to the volume of production, the volume increased due to the decrease in total production. while the use of heat from the boiler and the use of electricity in the production process still need to use at the normal level